How do I test exposure?

Measuring UV Exposure

It is the primary job of the screen maker to learn how to judge exposure. Invisible UV energy reacts with emulsion sensitizer and hardens the stencil so it won't dissolve with water and rinse down the drain. You block UV energy with a positive during exposure so the image area dissolves when you develop the stencil with water.

Screen makers can only expose one side of the stencil, so it is important for the UV energy to move through the stencil, all the way to the back, where the squeegee blade will rub the stencil where it is weakest.

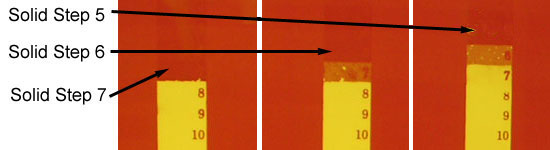

When the stencil doesn't hold in the mesh, it didn't get enough exposure. Start by checking the suggested exposure time on the product Technical Data Sheet. These estimated time charts are based on known commercial screen printing UV light sources on 305 mesh. You can measure your lamp with two exposures using a Stouffer 21 Step Scale to measure the stencil hardness, then refine your exposure with an exposure calculator.

To learn more, please visit the video link below: